No Oil Droplets Formation in Thermopile Flow Sensors

Used in Internal Combustion Engines

Tu XianZheng

Hot-film air mass sensors are commonly used for measuring an

air-mass flow, which include a resistor for heating

and one or two other resistors for temperature sensing. It has been

reported that when hot film air mass flow sensors are used directly in the

intake tract of the internal combustion engine or in a bypass channel to the

intake tract of the internal combustion engine, oil may deposit on the sensor

chips and, in particular, on the sensor diaphragms during operation or shortly

after the internal combustion engine has been shut off. This oil deposit may

result in undesirable effects on the measuring signal of the sensor chip, in

particular because an oil film affects the thermal conductivity of the sensor

chip surface, which results in corruption of the measuring signals or a signal

drift.

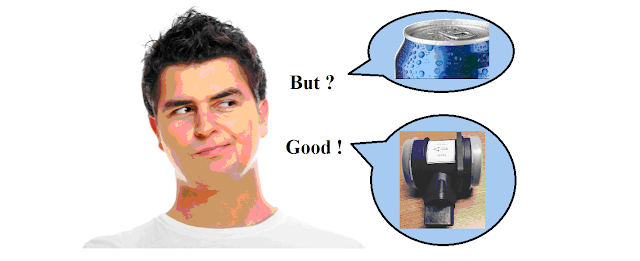

As well known, condensation can produce water droplets on the outside of soda cans or glasses of cold water. When warm air hits the cold surface, it reaches its dew point and condensed. As result droplets of water leave on the glass or can.

As well known, condensation can produce water droplets on the outside of soda cans or glasses of cold water. When warm air hits the cold surface, it reaches its dew point and condensed. As result droplets of water leave on the glass or can.

It is the same that when a thermal air mass flow sensor is

operated at the border region of the heated measuring areas oil accumulates and

over time results in oil droplets. The air flow drives the oil droplets on the

surface up to the boundary of the heated measuring area, at which a stronger

temperature gradient appears. The strong temperature gradient exerts a force

opposite to the force exerted by the air flow. Oil droplets thus accumulate on

the boundary line, which, when they reach a certain size, may be entrained

again by the air flow to then contaminate the surface of the measuring area. In

addition to the oil droplets, other contaminants also reach the surface of the

measuring area due to this effect.

How to solve this problem? Back to the above mentioned

condensation. Condensation of water occurs when water vapor within the air

cools enough in order to change into the liquid state. A good example of

condensation often occurs in the home during winter time, when water droplets

form on the surfaces of cold windows. If open the window to let the cold air

enter the room there will no any water droplets form on the surface of the

window. So the only way to solve the problem is to reduce the operation

temperature of the sensor. This can be done using a thermopile air mass flow

sensor instead of a hot film air mass flow sensor.

It does not respond to

absolute temperature, but

generates an output voltage proportional to

a local temperature difference or temperature gradient. A thermopile air mass

flow sensor is constructed with a heater for heating and several thermocouples for

temperature sensing. The thermopiles are in series and so the output voltage

due to temperature change is summed and increased over that of a single

thermocouple.

With this advantage, POSIFA has

developed thermopile air mass flow sensors with two group thermopiles

positioned at the two side of the resistor heater and each group consisting of

40 thermopiles. Since the summed output of each group is so great that the

operation temperature of the heater can be reduced as low as no condensation to

take place. For example, the operation temperature can be set 10 to 20 degree Celsius

higher than the air temperature. In this case condensation of oil vapor in the

air is almost impossible.

沒有留言:

發佈留言