Anti - Sound Wave Interference Thermal MEMS

Motion Sensors

Xiang Zheng Tu

It has been

reported that a research team of University

of Michigan

In

this research the accelerometers are capacitive

MEMS devices which are typically structured

with a diaphragm acting as a mass that undergoes flexure in the presence of

acceleration. As shown in the above figure two fixed plates sandwich the

diaphragm, creating two capacitors, each with an individual fixed plate and

each sharing the diaphragm as a movable plate. The flexure causes a capacitance

shift by altering the distance between two parallel plates, the diaphragm

itself being one of the plates. Under

zero net force the two capacitors are equal but a change in force will cause

the moveable plate to shift closer to one of the fixed plates, increasing the

capacitance, and further away from the other fixed reducing that capacitance.

This difference in capacitance is detected and amplified to produce a voltage

proportional to the acceleration. The dimensions of the structure are of the

order of microns.

It is not surprise that the

diaphragm of the accelerometer is also sensitive to acoustic pressure and works

like a capacitive MEMS microphone. A capacitive microphone is commonly formed by

a movable membrane and a rigid back plate, forming a structure with a plate

capacitor. The movable membrane responds and changes its position when the

acoustic pressure hit its surface, producing a capacitance variation between

the back plate and the membrane, which in turns produces a current flow

proportional to the distance variation between the membrane and the back plate.

There is no essence difference

between these two capacitive MEMS devices. It is true

that said Kevin Fu, U-M associate professor of computer

science and engineering, the fundamental physics of the hardware allowed us to

trick capacitive accelerometers into delivering a false reality to the

microprocessor. And their findings resonantly upend widely held assumptions

about the security of the underlying hardware.

However POSIFA’s

thermal MEMS motion sensors can make these things total different. Using the

POSIFA’s thermal MEMS motion sensors sound waves are no longer allowed to hack

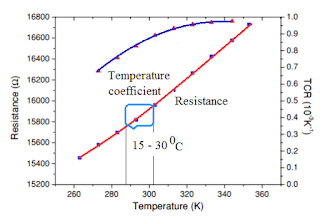

everything from phones to fitness trackers. Reference to the above figure a POSIFA’s thermal motion sensor comprises a thermal

isolated plate created in a silicon substrate, a resistive heater, and two

thermopiles both are formed on the surface of the plate. The laws of physics

teaches that the temperature field generated by a moving heat source is

asymmetry and able to be measured. In steady state, the vertical

cross-sectional temperature field is a sequence of symmetry concentric circles

each representing an isotherm on the lateral plane. When the heat source moves

the vertical cross-sectional temperature field will be skewed towards down

motion direction. The skewed lateral cross-sectional temperature field consists

of a contracted half plane and an expended half plane both are divided by a

line perpendicular to the motion direction. Since two thermopiles sensors are

placed on the plane around the heat source, all isotherms can be reconstructed.

A lot of useful information including the direction and velocity of the moving

heat source can be extracted form the reconstructed plane isotherms.

Acceleration is used to measure

the change in velocity, or speed divided by time. For example, a car

accelerating from a standstill to 60 mph in six seconds is determined to have

an acceleration of 10 mph per second (60 divided by 6). So with several

accelerometers on your smart phone, you can determine if the smart phone is

moving uphill, whether it will fall over if it tilts any more, or whether it’s

flying horizontally or angling downward. And you know how to tilt your smart phone

it can rotate their display between portrait and landscape mode accordingly.

The thermopile

flow sensors can replace capacitive accelerometers for measuring the speeds of

any moving objects including smart phones. The working principle is based on

the fact that a moving object experiences an apparent wind that is the wind in

relation to the moving object. Suppose

the object is a riding bicycle on a day when there is no wind. Although the

wind speed is zero, the rider will feel a breeze on the bicycle due to the

bicycle is moving through the air. This is the apparent wind. On the windless

day, the measured apparent wind will always be directly in front and equal in

speed to the speed of the bicycle. It is very clear that it is impossible for the

thermal motion sensors to response sound wave because there is no sound wave

sensing mechanism to take place.