Thermopile Temperature

Sensors

Xiang Zheng Tu

POSIFA’s thermopile sensors are based on the

technologies of silicon micromachining and CMOS manufacturing. In the thermal sensor

fabrication a part of silicon substrate is removed by a porous silicon etching process,

leaving on top only a thin sandwich layer membrane of PECVD SiO2/Si3N4,

which has low thermal conductivity. On the membrane a resistor and two

thermopiles are formed there which are used as the main device elements of the

sensor. The resistor is located along the central line of the membrane and made

of a deposited thin polysilicon film. Two thermopiles are located on the two opposite

sides of the resistor respectively. The thermopiles have alternate hot junctions

disposed near the resistor and alternate cold junctions expending out of the

membrane and ended on the bulk part of the silicon substrate. The junctions are

formed by both a deposited thin polysilicon film and a deposited thin aluminum

film.

The thermopile sensors can be used

as a lot of different thermal sensors with a little modification which include fluid

flow sensors, gas thermal conductivity sensors, vacuum sensors and temperature sensors.

In working of the temperature sensors the polysilicon resistor is used as a heater

and one thermopile is used for temperature different sensing.

Since the membrane is heated by

the heater the temperature different generates between the membrane and the bulk

part of the silicon substrate. It is need to know that the low thermal

conductivity of the membrane is beneficial to the temperature different maintain.

The power dissipated in the polysilicon resistor causes its

temperature to rise above a room temperature by:

TPR-Troom=(V2/RPR)θ (1)

Where

TPR=the raised temperature of polysilicon

resistor due to internal power dissipation

Troom =the

reference temperature of polysilicon resistor

V=the driving voltage of polysilicon resistor in V

RPR=the value of the polysilicon resistor in ohms

at TPR; and

θ=the self-heating polysilicon resistor ting effect in

°C/mW.

For an ideal thermocouple, the open-circuit voltage obtained

is proportional to the temperature difference between the hot junctions and

cold junctions which are constructed of polysilicon film and aluminum film,

∆V=S(TPR-Troom) (2)

where S is the relative Seebeck coefficient, expressed in

µV/K. The relative Seebeck coefficient of a junction can be calculated as the

absolute value of the each Seebeck coefficient of polysilicon and aluminum;

that is,

S=SPoly−SAl (3)

Because a voltage is produced when a temperature difference

exists between the two junctions of the thermocouple junction pair, the

thermocouple can be used as a detector of incident radiation. In open-circuit

operation the output voltage produced is usually low, on the order of a tenth

of a microvolt per degree celsius of temperature difference for a single

junction pair. In order to increase the output voltage, several junction pairs

may be connected in series. The responsivity is then increased by n if n

thermocouple junction pairs are placed in series; that is,

∆V=n(SPoly−SAl)

(TPR-Troom)

(4)

Such a device is called a thermopile.

Combining equation (1) and (5) results the equation as:

∆V=n(SPoly−SAl

) (V2/RPR)θ (5)

The resistance of a polysilicon resistor is specified at a

room temperature, any other resistance at another temperature is determined by:

RPR=Rroom[1+α(TPR-Troom)] (6)

Where

Rroom=the resistance at a room temperature in ohm

α=the temperature coefficient of the resistance

Rroom=the resistance at a room temperature in ohm

α=the temperature coefficient of the resistance

After replacing equation (6) into equation (5) an equation

is obtained as

∆V=n(SPoly−SAl

) V2θ / Rroom[1+α(TPR-Troom)] (7)

From the equation (7) it can be

seen that the output voltage ∆V of the thermopile is inversely

proportional to the resistance Rroom at a room temperature.

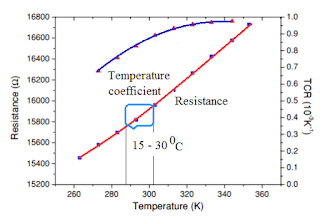

An example of a resistance and temperature coefficient of

polysilicon resistors with temperature are shown in the following figure.

These polysilicon resistors were made of a 700 nm thick polysilicon

films that were grown at 580◦C in furnace by low-pressure chemical

vapor deposition (LPCVD). The polysilicon films were partially implanted by

boron (p-type) and phosphorus (n-type) from 4×1015 to 10×1015

at cm−2 doses. The implant energy for each group doses was 70-80kev.

Afterward, the doped polysilicon films were annealed in furnace at 1000◦C

for 30 min to activate dopants and obtain a uniform doping profile through the

whole thickness and repair the defects in the crystalline structure.

As shown in the above figure the resistance of the

polysilicon resistor varies with temperature. If the room temperature Troom

rises from 150C to 300C the resistance

will change about 200Ω for a polysilicon resistor with 15800Ω at 200C.

Since the output voltage ΔV of the thermopile is inversely proportional to the

resistance of the polysilicon resistor (as a heater) a specified room

temperature can be determined from the measured output voltage of the

thermopile.

Off cause polysilicon resistors without

thermopiles can also be used as temperature sensors. But common types of

resistor temperature sensors are made from platinum instead of polysilicon. Platinum

has temperature coefficient α = 0.003925 Ω/(Ω·°C) and polysilicon with sheet resistance ranging from 25 to 150Ω/□ has temperature

coefficient α =1x10-3 Ω/(Ω·°C). So

the sensitivity of the platinum resistor temperature sensors is much higher

than the polysilicon resistor temperature sensors.

Thanks to CMOS manufacturing technology it allows POSIFA to

integrate up to 40 pair of thermocouples in each thermopile. That means the

responsivity of the thermopile temperature sensors is increased by 40 which is comparable

with platinum resistor temperature sensors.

There are three additional advantages that justify the use

of MEMS and CMOS manufacturing technologies.

1. CMOS offer the thermopile

structure materials with higher Seebeck coefficient.

2. CMOS beneficial to tune the main

characteristics of the thermopiles by doping.

3. MEMS allow the thermal capacity

of the thermopile to be reduced effectively by miniaturization.

Thus POSIFA’s thermopile temperature sensors have the best

potential to satisfy the demands on miniaturization and mass production.

沒有留言:

發佈留言